Flash Cutting

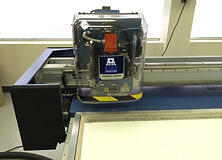

Flash Cutting is used when a project requires a dieless system. ACRO INDUSTRIES’s Flash Cutting process utilizes a CNC machine to hold and cut precision material from .001 of an inch up to 1 inch thick. The Flash Cutting process provides more customization options and faster production turn-around times.

ACRO INDUSTRIES’s Flash Cutting process allows you to easily produce prototypes from CAD drawings, shaping your unique product in a matter of minutes.

Flash Cutting applications are numerous, and can be used with a number of materials. Flash Cutting is perfect for projects where aesthetics are important, as the process doesn’t cause concavity and produces clean edges. Flash Cutting provides efficient use of materials as well as extraordinary precision and yield.

Flash Cutting vs. Die Cutting

DIE CUTTING allows you to cut a number of different materials into shapes and designs leaving an extended liner whereas FLASH CUTTING uses a machine that holds a blade in place while accurately and cleanly cut through the production material with exact measurements. FLASH CUTTING is suitable for projects that require rapid prototyping and aesthetically perfect parts

Equipment Capabilities

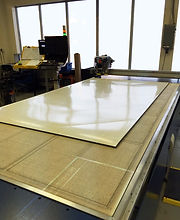

With 2 ATOM Flashcut Flex 30155 dieless knife cutting tables. Our manufacturing / cutting area enables ACRO INDUSTRIES to cut parts as large as 3050mm x 1550mm (121" x 61").

The Benefits of Flash Cutting

- Optimal material utilization with advanced yielding technology to maximize production efficiencies and control costs. The software provides for optimization of layouts and shape within shape cutting.

- Rapid prototyping and samples

- Faster turnaround time for customer parts and products

- The knife cutting table can cut materials up to 1 inch in thickness

- A high quality “Clean Edge” on manufactured parts

- Patterns can be loaded directly from CAD programs to begin immediate production

- No tooling required so there are no traditional tooling costs or waiting time for tooling

Rapid Part Prototyping

No tooling requirements help designers and engineers move quickly from design to production quantities to meet their “speed to market “ objectives. Our flash cutting process can quickly turn out prototype parts for testing:

- Customer design on a CAD file downloaded.

- ACRO INDUSTRIES produces prototype or sample for immediate testing.

- Test prototype.

- Adjust and produce another prototype, if necessary.

- Customer approval.

- Begin production run.

- Ship finished parts.

Materials Capability of the Flash Cutting System

The flash cutting system is CNC based and enables ACRO INDUSTRIES to manufacture OEM and custom parts quickly and cost efficiently from a wide variety of flexible materials, including: foams (open and closed cell), rubber and its by-products, films, silicones, sponge, plastics, cloth and fabric, felts, textiles, tapes, adhesives, filtration materials, foils, fiber gasket material, insulation, cork, leather, and many other non-metallic materials from a wide variety of manufacturers.

Flash Cut Products and Applications

This new CNC cutting equipment is the newest technology in industrial cutting and further enhances ACRO INDUSTRIES’s ability to manufacture and fabricate OEM and custom parts from flexible materials, including the following products and applications:

- All types of non-metallic gaskets, including engine gaskets and housing gaskets

- Dampeners (noise and vibration)

- Filtration products

- Heat dissipative products

- Heat foils

- PPE (Personal Protective Equipment)

- Point of purchase displays and signage

- Protective packaging

- Protective covers

- Skid plates

- Touch screens

- Traction enhanced products

This means your order is produced accurately and On Time. Our Just in Time Delivery Scheduling, the ACRO Quick Production Program is available to minimize your inventory and warehouse needs and save money for you.